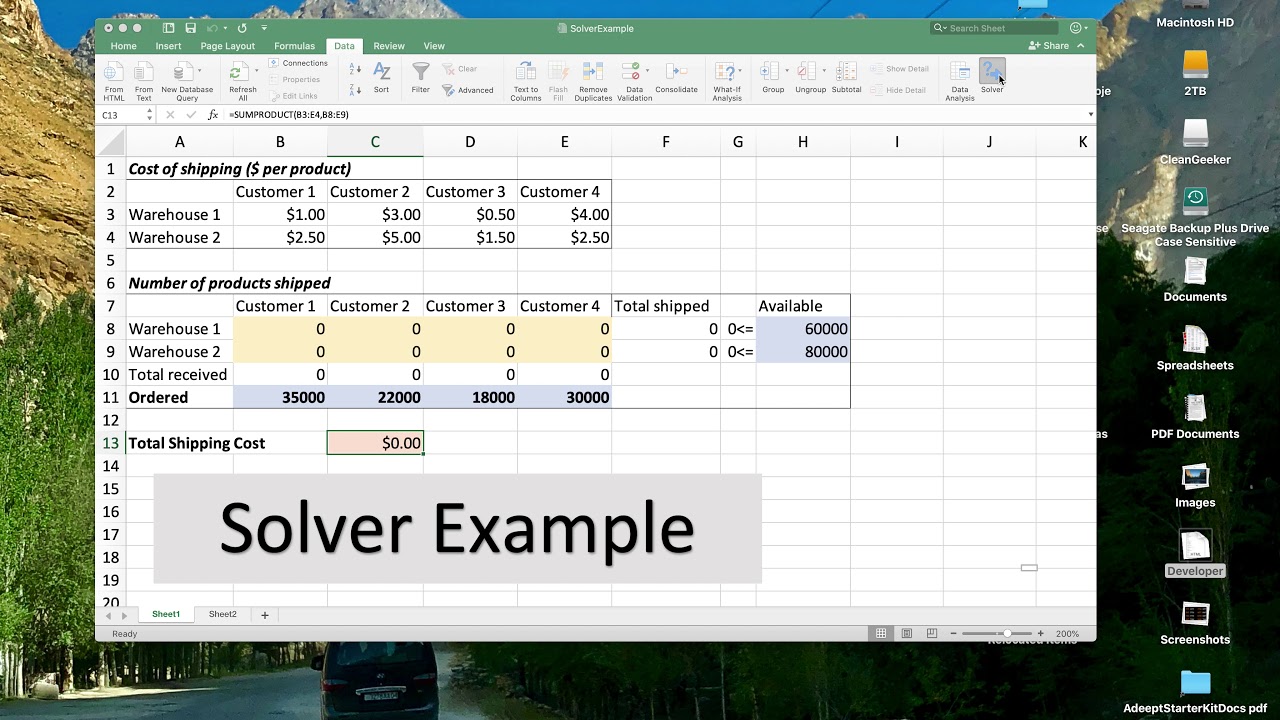

Then enter the unit storage capacity for each distribution center. Start by entering each store’s demand that gives us a total demand of 1190 units in this case. Click on each facility in the SCM Globe supply chain model to see information for product demand, storage capacity, etc. The first step in our process is to enter the data we need from the supply chain model in an organized manner. Now that we have defined the problem and the network model, it’s time to move to Excel to enter the data and make our analysis. The supply chain model shown in the screenshot above can also be represented with an abstract network diagram like the one below: Moving to Excel Solver

#PROCESS LAYOUT EXCEL SOLVER TRIAL#

We are glad to provide a free evaluation account to instructors, students and supply chain professionals interested in exploring SCM Globe simulations - click here to request an account - Get Your Free Trial Demo In the screenshot below you can see the facilities and the network of possible roads to use in delivering products from one facility to another. Facilities are defined and their icons are put on the map using the SCM Globe supply chain modeling and simulation app. It’s a simple network with two stages: there are three Distribution Centers, and the other eight facilities are Stores. The maximum storage capacity of each source facility.īelow is the supply chain network we are going to use.Facility locations and distances between each source and destination facility.Product demand at each destination facility.Here is a list of information needed to solve a transportation problem: a warehouse) to different destinations or markets in such a way as to minimize total transportation cost while satisfying all the supply and demand constraints. The transportation problem is one of the subclasses of a linear programming problem in which the objective is to transport products stored in a facility (e.g.

By doing it right, you will be managing production and inventory effectively, speeding processes, and improving customer service. Allocating supply sources to facilities properly has a considerable impact on your supply chain’s financial and operating performance. The goal is to satisfy demand, which means being responsive, while also being efficient, which means having the lowest transportation cost. In this article, we will be exploring one of the fundamental cases of market and supply allocation it’s called the Transportation problem. Therefore, supply chain and logistics managers must take advantage of transportation’s potential in terms of opportunities for cost reduction. Transportation costs are a significant component of the overall supply chain costs.

0 kommentar(er)

0 kommentar(er)